Graphene breakthrough 🔋

Catch the 1E bus from central Belgrade, Serbia, and you’ll be riding the future.

The five Chariot e-buses that operate on this route are some of the first in the world to run solely on supercapacitors, a fast-charging alternative to batteries that could revolutionize how we store energy.

Instead of holding electricity as chemical potential, like a battery, supercapacitors (also known as ultracapacitors) store it in an electrical field, like static collecting on a balloon. Because there’s no chemical reaction going on, they don’t degrade like lithium-ion batteries, which rely on rare-earth metals and can end up in landfill after two years. This means that you can charge them much more quickly – a five minute charge for one of Belgrade’s buses can carry it up to 18 km.

There are two reasons supercapacitors haven’t yet replaced batteries in our electric cars and electronics: they hold less energy in the same amount of space, and they can’t hold it for as long. A fully charged supercapacitor can leak down to empty in hours, rather than days.

That’s fine for a bus that can be charged at every stop, but less useful for a car that needs to run all day. But now, a host of researchers and start-ups are trying to make supercapacitors better. To do it, they’ve turned to one of the most hyped materials in history: graphene.

Discovered at the University of Manchester in 2004, graphene - which consists of thin flakes of carbon atoms arranged in a hexagonal structure - was quickly hailed as a wonder material. It is strong and light, with a high surface area, and it’s an excellent conductor of both heat and electricity. But, the promised graphene revolution is yet to materialise. “It is still in its teenage years,” says James Baker, the CEO of Graphene@Manchester.

Belgrade’s buses use supercapacitors made from layers of activated carbon, which is coated onto conductive plates immersed in an electrolyte solution. Graphene is also a form of carbon, but because of its huge surface area (which determines the performance of a supercapacitor) it has the potential to radically improve the performance of supercapacitors to a level where they become practical for electric cars and consumer devices. It could create smartphones that charge in seconds, and cars that can refuel while they’re stopped at a set of traffic lights.

The market for graphene batteries is predicted to reach $115 million by 2022, but it has huge potential beyond that as the technology improves, and a number of companies have attracted significant interest in their work.

These include Chinese company Dongxu Optoelectronics, which announced a graphene supercapacitor with the capacity of a typical laptop battery that could charge up in 15 minutes, instead of a few hours. Barcelona-based startup Earthdas has used graphene to create supercapacitors for electric bicycles and motorcycles, which can be charged 12 times faster than lithium-ion batteries. It plans to start selling them later this year.

Many of this new breed of supercapacitors aren’t strictly graphene, a term which technically refers only to the two dimensional sheets of carbon. Although it already has a huge surface area, efforts are ongoing to increase that by adapting graphene in different ways – poking tiny holes and channels into it, or texturing it at the nanoscale level.

Estonian company SkeletonTech offer a range of products that incorporate curved graphene, while Oxfordshire-based ZapGo use a mixture of graphene and carbon nanotubes that resembles peaks and valleys rather than just flat layers. Their first products – an electric scooter, and jump-starting kit for cars – will hit the market later this year.

There’s still work to do before graphene supercapacitors can hold their charge for long enough to be a practical alternative to lithium-ion for most applications, however. Some have suggested hybrid systems – supercapacitors for fast-charging, with traditional batteries for long-term storage.

Another potential problem could be scaling up production – because of the hype, the graphene industry has become a minefield of broken promises and shoddy quality control. Last month, the UK’s National Physical Laboratory launched an initiative to help companies verify whether they’re actually getting what they pay for when they buy graphene.

Although it is much more environmentally friendly than lithium-ion overall, and can be much more easily recycled, the most common production processes for graphene still involve harsh chemicals, which may not be sustainable if it’s going to supply an electric car pool that could reach 125 million vehicles by 2030. But, if researchers can crack these problems – and they’re working on it – then graphene could fundamentally change the way our world is constructed.

“The exciting thing for me is when you start looking at the whole system and doing that in a different way,” says Baker. “Could I actually make my structure into an energy storage device? Then you start getting the benefits of light-weighting, together with increased storage, maybe add flexibility into that and suddenly you can get some quite novel types of solutions.”

In the south of France, Ulrich Grape and Pascal Boulanger of NAWAShell have plans to build carbon-based supercapacitors into the structure of electronics, vehicles and even footwear. Their technology uses carbon nano-rods - billions of them per square centimeter - which can be incorporated into or coated onto other materials such as flexible polymers, for foldable phones and wearables, or strong and light carbon fibre.

It could be used to make laptops with batteries built into the case, or electric cars that store energy in their doors or chassis instead of in bulky battery packs.“In a way, it will be like having a battery free car,” says Grape, who estimates that with NAWAShell’s current level of technology, a small structural battery in the chassis of a light electric car could add an extra 15km of range. Eventually, they could build energy storage into the very walls of your home. “You integrate a new function into a composite,” explains Boulanger. “You do not change the mechanical behaviour of the structure.”

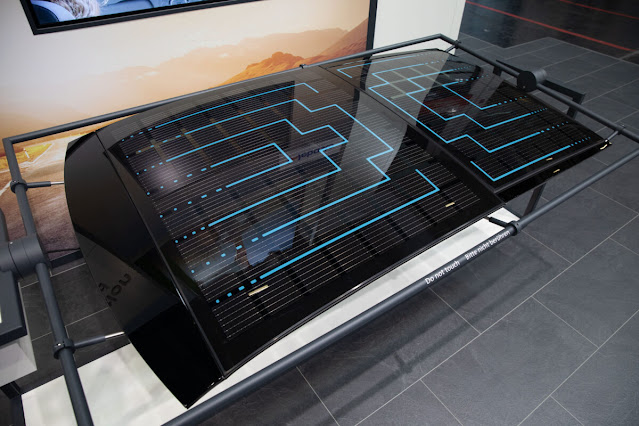

In 2017, Lamborghini announced a partnership with the Massachusetts Institute of Technology to develop the Terzo Millennio, a concept for an electric supercar powered by graphene-like materials built into its carbon fibre bodywork. The technology is rapidly improving – and could be in our phones by the early 2020s – but it will be a while before it’s good enough to power a Prius, let alone a high-end sports car. Eventually, supercapacitors made from graphene or materials like it will form an important part of our world. But for now, we’ll have to settle for a Belgrade bus ride.

Credit:

Amit Katwala is an editor and writer at WIRED, based in London. He works across the UK print magazine and on features, science and culture. He graduated from the University of Oxford with a degree in experimental psychology. His latest book is *Tremors in the Blood: Murder, Obsession and the...

Comments

Post a Comment